Everything You Need to Know About Load Cells and Their Technology

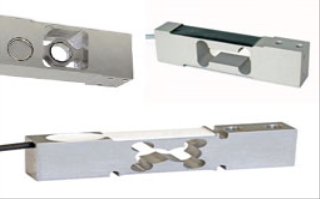

In the dynamic industrial world, load cells are one of the most ubiquitous components that cannot be overlooked. Wondering what load cells are? Well, they fall under the umbrella of transducers or electro-mechanic sensors that helps convert force into electrical output. The cell functions to measure weight or force and it has an effective design that depends on the electricity flow and material deformation. Load cells are versatile devices offering accurate performance across diverse applications. All commercial and industrial processes use load cells as an effective way to measure weights and forces across systems.

Load Cell Technology

There are different types of load cells. While the resistive load cells work on the principle of piezo-resistivity, the capacitive load cells function on the principle of the change of the capacitance. Typically, capacitance is a system’s ability to hold a certain amount of charge when the voltage is applied to it. Also, load cell designs can also be differentiated as per the type of output signals generated (hydraulic, pneumatic, electric) or according to the way how they detect weight (compression, bending, tension, shear, etc).

Load cells find their uses in geotechnical fields. They are typically used to monitor deep sea foundations in excavation bracing like struts, anchors or tiebacks, soldier pile, and retaining walls. Load cells can also be used to keep tabs on tunnels and shafts. Working on the classic principle of Wheatstone bridge, load cells need the application of voltage to opposite nodes.

How do load

cells work?

Load cells

involve the use of geotechnical instruments and they can’t wok without being

paired up with sensors. One of these sensors is the strain gauge. Strain gauges

are fundamentally thin elastic materials made up of stainless steel. They are

fixed inside the load cells and they have a specific resistance directly

proportional to its width and length. When the force is applied on the load

cell, it stretches or bends causing the strain gauge to move and when the

cross-section and length of the strain gauge alters, its electrical resistivity

also gets changed, thereby changing the overall output voltage.

Environmental Conditions

The load cell

may face versatile environmental conditions. However, you must ensure to

protect it from the exterior environment to make sure it has an efficient

performance for the intended usage timeline. A few load cells are in potted

form and their cavities get filled with resin material or epoxy to cover the

anodic components. The protection helps guard the circuit system from humidity

and outside damage while dissipating heat.

A few load

cells also exhibit hermetic seals to enable environmental

protection. Fully welded seals provide a robust and airtight enclosure that

helps the load cell to stand up during challenging environments.

You may find FM and ATEX certificates for certain load cell types that indicate it is safe to use the equipment in dangerous or explosive environments.

Conclusion

You must ensure

that the load cell gets properly installed and aligned to make the most of its

performance. You can follow the manufacturer’s recommendations to get the best

results from the reliable device and ensure long-lasting usage.

Comments

Post a Comment