Compression load cells: A simple yet effective design!

Are you looking for a load cell to

maximize your production line’s efficiency? Load cells are ubiquitous in every

factory or manufacturing plant. When you need to accurately measure the weight

of a high number of products without compromising on the precision of the

measurement, load cells are practically the only cost-effective solution in the

market. You can find multiple varieties of load cells in the market and may get

confused when choosing the right one.

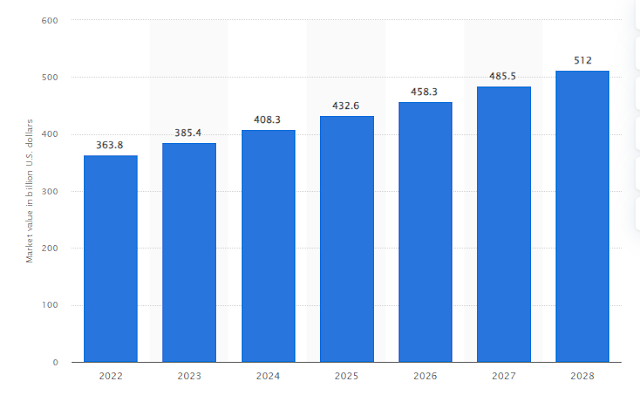

(Source: https://www.statista.com/statistics/876489/food-packaging-market-value-forecast-worldwide/)

The food packaging industry is on a trajectory of constant growth in the coming decade growing from USD 363 billion in 2022 to USD 512 billion in 2028. The global population and the growing middle class are considered to be the primary factor behind this growth. Companies looking for an early start should invest in high quality packaging machinery like load cells, X-ray scanners and filling machines.

The most commonly used types of load cells to consider for your

production line:

- Compression load cells: These

load-measuring devices work on the compressing or squeezing effect of a

load under gravity. Due to the nature of their operating principle, compression load cells need

to be below the load that is to be measured. The load cell then senses the

pressure exerted on itself by the load. This information is then converted

to a digital reading which can be interpreted by the observer.

- Single point load cells: Similar to

any other load cell, single point load cells are used to measure the force

exerted on them and convert it to a digitally accessible reading. What

makes Single point load cells unique is their ability to accurately

measure weight even when the load is positioned off-centre. Other

traditional load cells require the load to be positioned at the centre to

get precise readings, unlike the single-point type.

- Tension load cells: Often called the S-type load cell, these are considered to be one of the most versatile load cells in the market. Used in a range of industrial applications, thanks to their adaptability to diverse weight measurement requirements. Tension load cells can be used either below the load or on top of the load depending on the requirements. This ability of the load cell makes it a bidirectional tool which can be used both for measuring the tension and compression load by changing the setup.

What makes compression load cells unique?

The simplicity of a compression load cell cannot be denied when looking at its build. Just like any other load cell, compression load cells are transducers. Most commonly a cylindrical body is used inside which strain gauges are attached. The cylindrical body deforms under the pressure exerted by a load. This deformity carries forward to the strain gauges. The change in the physical structure ultimately gives rise to a change in the voltage output of the strain gauge. This change in voltage is the electrical signal which is then converted to the associated load value for easy reading.

In conclusion

Compression load cells are the go-to

solution in industries for highly reliable static load measurement needs. Their

simple yet robust build quality means a long service life without any need for

frequent repairs or maintenance. If you are looking for load cells

in Australia, you can choose from reputed

manufacturers with a long track record of producing high-quality and reliable

industrial tools. You can find the best manufacturers

online with a simple search query. You can contact the manufacturers and

communicate your needs for complete assistance and the best value for your

money.

Comments

Post a Comment