What steps can you take to ensure optimum food safety: Let us explore!

Food safety is not something consumers have to worry about all the time: Thanks to the regulations put in place by governments. However, the story for food producers or packagers is different. Food manufacturing companies adhere to the most stringent food safety practices to ensure their product matches all safety standards and is safe for consumption. Using the right machinery for the job goes a long way in simplifying this critical process. With various industries around the world ramping up the use of professional-grade food testing machinery, early adopters will benefit the most.

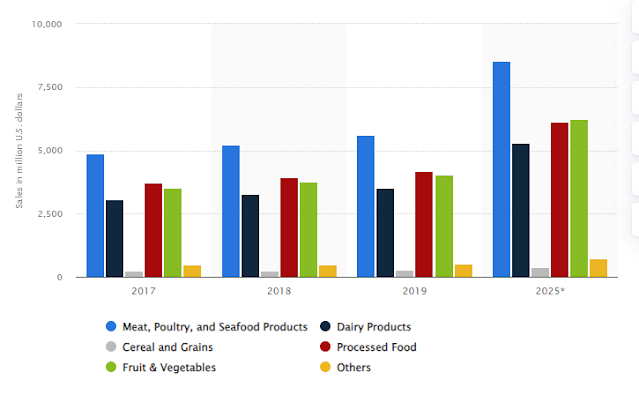

The global food

safety testing market by category.

(Source:

https://www.statista.com/statistics/1286148/global-food-safety-testing-market-by-food-type/)

Need for food safety standards:

Everyone agrees that we should have the right to obtain and consume

nutritious and safe food. To ensure adequate safety standards,

the adoption of testing machinery like X-ray scanners is becoming mainstream

scenario. Especially in the meat, poultry and dairy segment, the demand of

testing machinery is expected to skyrocket in the coming years according to

Statista. The diseases and

health risks of consuming expired or contaminated food can be severe and

life-threatening. So it is a worldwide practice to maintain the utmost hygiene

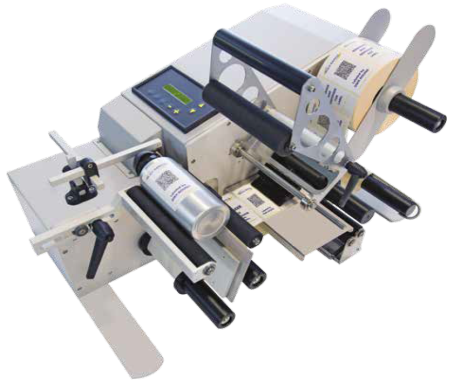

standards when producing food products. The packaged food industry is required

to label the necessary information like manufacturing date and allergen

information on the package so that the consumers can check for themselves

whether the packaged product is safe to eat.

How to ensure optimum food safety?

The only way to make sure a food article is safe to eat is to get rid of

contaminants. Depending upon the type of contamination, food may create

different problems if consumed. Materials like low-quality plastic, broken

tools, metal pieces or unwanted hazardous chemicals may cause physical mouth

injury, obstruction in the digestive canal or poisoning. This is why it is wise

to use high-quality packaging, labelling and inspection machines when building

an assembly line for food products.

X-ray food inspection: The best in the

market!

When your factory is producing hundreds or thousands of packaged goods per

day, it is nearly impossible to check the contents of each package. The high

output of a modern assembly line can easily overwhelm human eyes, so an

automated solution is required. The X-ray for food inspection machines are belt-fed and can automatically

scan through the produced goods without needing any physical human

intervention. A supervisor may keep a watch on the scanned contents and take

action if contaminants are detected in the final product.

What to look for in an X-ray food inspection

machine?

The duties of an X-ray food inspector are straightforward. We can judge

these machines on three factors: Speed, accuracy and reliability. In terms of

speed look for a machine with 60 to 90 m / min of linear speed and a capacity

of 25,000 grams. Dealing with food, pharmaceuticals or other similar goods

requires the machine to be protected from food and pharmaceutical chemicals. An IP65 rating

should be sufficient for protection against moisture, dust and other

substances. Additionally, the best modern food inspection machines come enabled

with a Windows operating system for a powerful yet convenient software

framework.

In conclusion

X-ray inspection machines are not only part of the food industry but also

an essential part of the cosmetics, pharmaceutical and chemical industries. Any

manufacturer looking to provide reliable high-quality goods to its customers

knows the value of inspecting final product output that reaches its customers. Paired

with the best filling machines, this duo can skyrocket

your production efficiency.Investing in a high-quality X-ray inspection

machine is a no-brainer. You can find the best inspection machines online in Australia with a quick & easy Google search.

Comments

Post a Comment